- Taiwan-based TSMC, the world's biggest chipmaker, announced a $40 billion investment in Arizona last week.

- That's despite TSMC's founder previously calling US chip production an "expensive exercise in futility."

- The investment could help achieve geographic diversity and shore up support from the US.

Last week, Taiwan Semiconductor Manufacturing, the world's biggest chipmaker, announced it would be making the largest foreign direct investment in US history. But in the past, the company's leadership has been skeptical of making chips in the US.

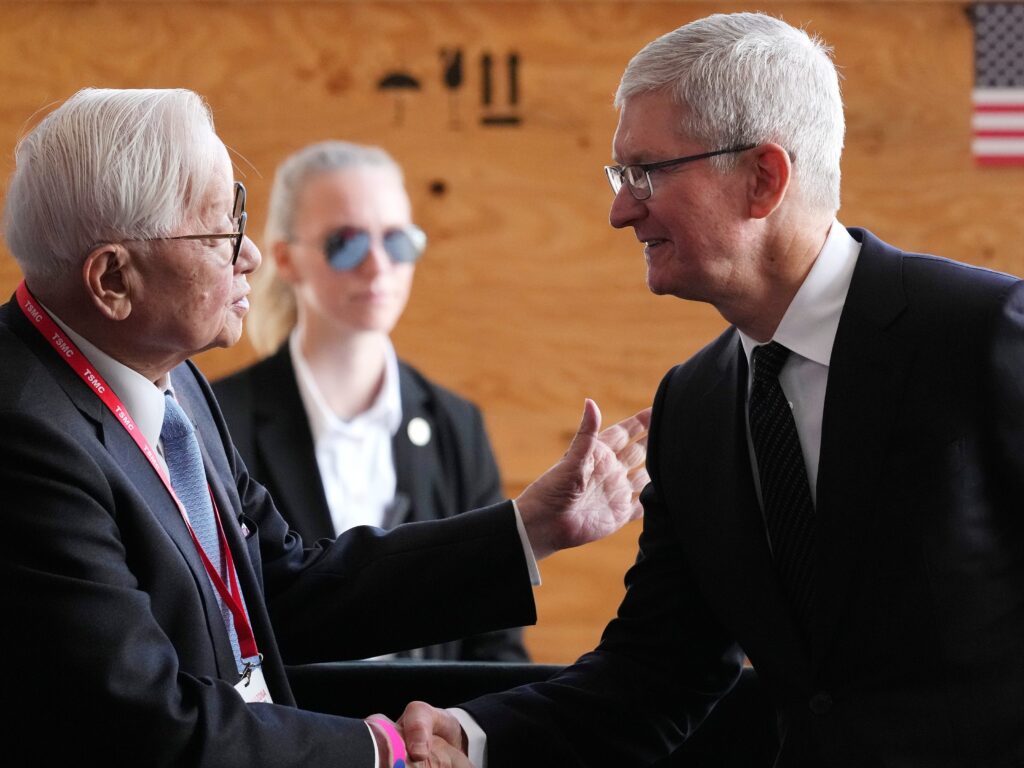

Last Tuesday, TSMC announced it would be opening a second factory in Arizona, increasing the company's investment in the state from $12 billion to $40 billion. TSMC's founder Morris Chang, however, has argued the investment isn't prudent for TSMC nor the US.

In April, Chang told The Brookings Institution the US's push to increase domestic chip production would be "a wasteful, expensive exercise in futility," citing "a lack of manufacturing talents" in the US, as well as his opinion that "manufacturing chips in the US is 50% more expensive than in Taiwan."

The US has taken steps to increase domestic chip production because it's reliant on TSMC's Taiwan factories for the manufacturing of products that include cars, PCs, iPhones, and washing machines. In the event China — which claims the island as its own — invades the island and chip production screeches to a halt, there could be trillions of dollars in economic losses. And many experts say it's just a matter of time before an invasion happens.

However, experts are skeptical that the Arizona factories will significantly reduce the US's reliance on Taiwan when both are completed in 2026, and Chang's comments suggest the investment could face even more basic challenges.

It may be in TSMC's self-interest to invest in Arizona, despite the business challenges

Despite the business obstacles, there are a few reasons TSMC many have not only decided to build the first factory in Arizona, but add a second.

First, the cost of chip production in the US might not ultimately be "50% more expensive."

"It's more like 15 to 20% more expensive," Dylan Patel, a chief analyst at the semiconductor research and consulting firm SemiAnalysis, told Insider. "The US will likely subsidize that penalty away, so the cost differential will not actually be much."

The factories will be partially subsidized by the US government through the CHIPS and Science Act, a package passed in August that provided $52 billion to boost US semiconductor chip production.

And even if production is more expensive, Patel says TSMC's customers will be "happy to pay a little bit more" to ensure supply chain diversity, something many companies are focused on given the supply chain challenges of the last few years.

This includes Apple, TSMC's largest customer that accounted for 26% of its revenues last year. Apple CEO Tim Cook has already said the company will be the factories' largest customer once they go online.

"TSMC leadership sees the benefit in having some geographic diversity in its operations," Martijn Rasser, a former CIA officer who is now a security and technology expert at the Center for a New American Security, told Insider, "particularly when it is heavily courted by the governments of the world's leading economies."

As Rasser alludes to, winning the favor of the US government could be another factor at play.

Chang told Brookings as much in April. While he said it wasn't his decision to build the first factory in Arizona, Chang said he did so "at the urging of the US government."

And TSMC may have good reasons to ensure it's on good terms with the US.

According to Stratechery's Ben Thompson, if the Arizona investment "is the price of shoring up U.S. support for Taiwan" in the event of a Chinese invasion, "that is the best possible insurance policy the company could buy for its operations that truly matter, which are intrinsically tied to Taiwan."