- Furniture shipments are still delayed due to a shortage of foam used in mattresses and couches.

- The Texas freeze impacted foam manufacturing, and consumer demand for furniture remains high.

- Production is now at normal levels, but furniture-makers could face competition from automakers.

Foam shortages are continuing to hamper the furniture industry, leading to delays that likely won't be resolved until next year.

Consumer demand for products that include foam, like couches and mattresses, remains so high that the foam industry is struggling to keep up. The shortage, combined with shipping backlogs that are holding up raw materials and a truck driver shortage that's delaying deliveries, means that some furniture that's ordered now won't even ship until 2022.

Russ Batson, executive director of the Polyurethane Foam Association, an industry group that represents foam manufacturers, told Insider in an email on Monday that while foam production has now returned to pre-pandemic levels, it's "inadequate to meet strong consumer demand" for products, demand that spiked due to a rush in home-buying during the pandemic and a desire to trick out our spaces after spending so many months at home.

The foam industry has faced other challenges in 2021 aside from consumers clamoring for furniture. When unprecedented winter storms hit Texas in February 2021, the region experienced a deep freeze that damaged homes nad businesses and caused pipes to burst.

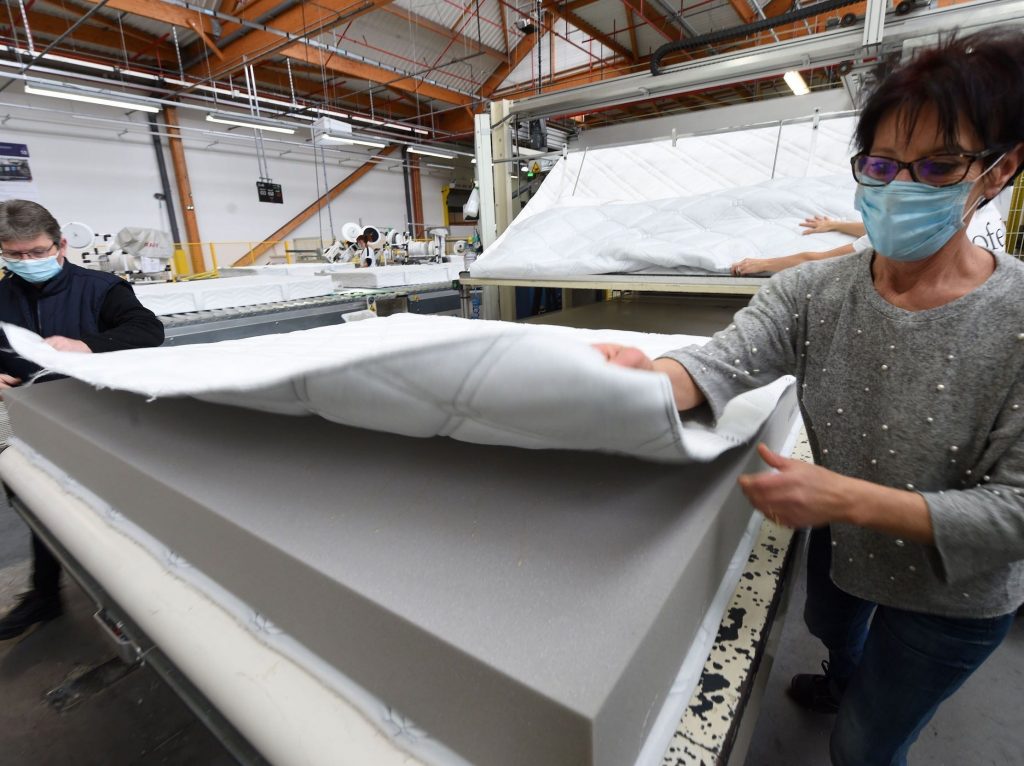

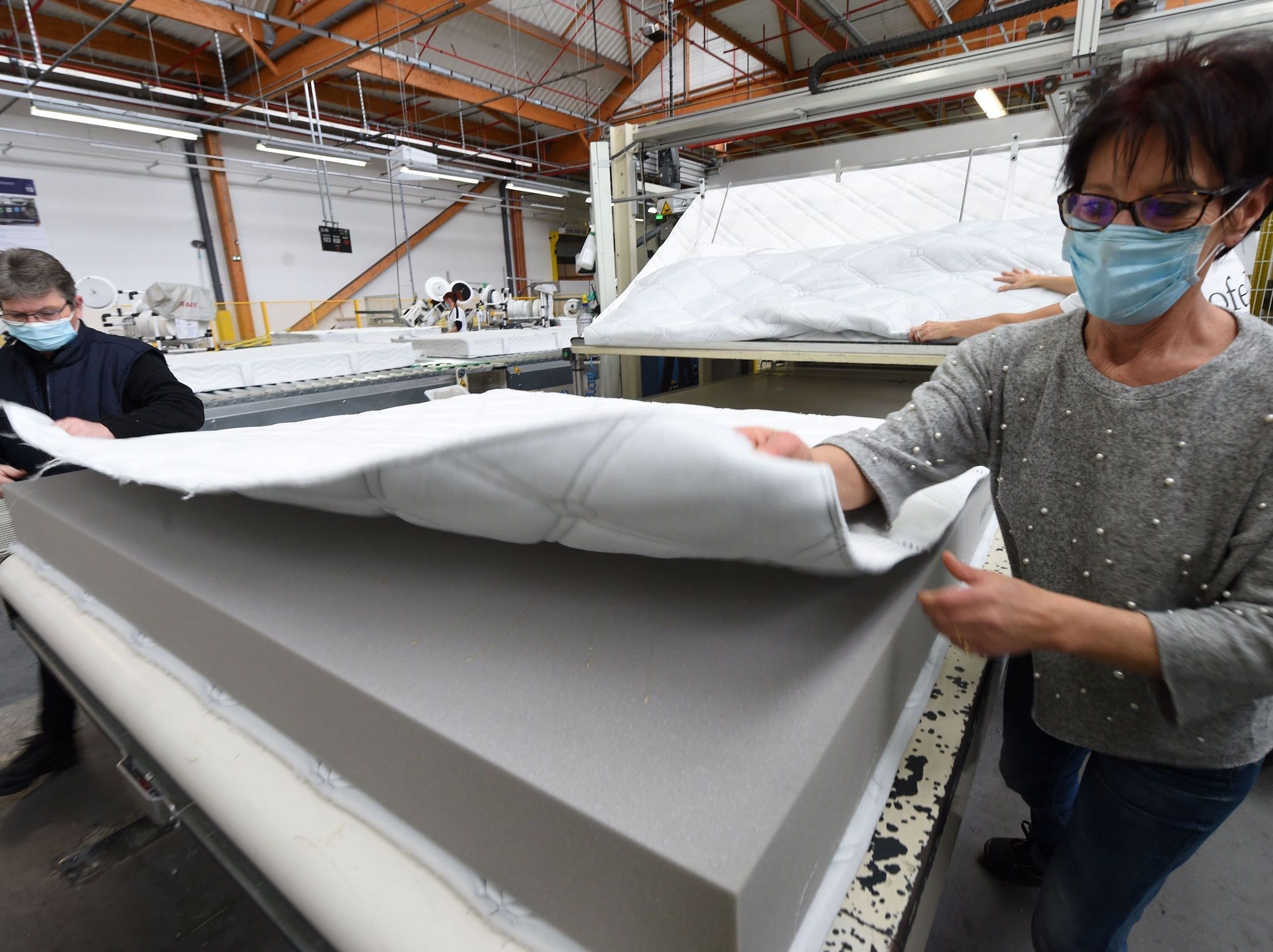

That weather also shut down the chemical plants that make propylene oxide, a key chemical in polyurethane foam – the same foam that's used in mattresses, couch cushions, and seats in cars, the Houston Chronicle's Diane Cowen reported earlier this year.

Bob Patell, the CEO of LyondellBasell, which produces propylene oxide along the Gulf Coast, said at a JPMorgan conference in March that the Texas freeze wiped out 10% to 14% of its annual petrochemical supply, according to the Chronicle.

As a result of the short foam supply, furniture makers in across the US were forced to cut production hours or raise prices. One San Francisco-based furniture manufacturer told Slate's Aaron Mak in July that foam manufacturers were rationing in an attempt to give furniture-makers "something versus nothing."

But now, even though production levels have stabilized, the furniture industry could soon face another challenge: increased competition for foam.

Batson of the PFA warned earlier this year that couch and mattress companies are lucky, in a way, that they're not seeing foam diverted to automakers. As car companies grapple with an ongoing semiconductor shortage, they're making fewer vehicles - consulting firm AlixPartners estimated last month that as many as 7.7 million fewer vehicles will be made this year. Fewer cars means automakers require less foam to put in vehicle seats.

But Batson told Insider this week that furniture-makers may need to brace for an even tighter supply of foam.

"When the auto industry sorts out its more complex supply chain challenges," he said, "that will exert additional pressure on foam supplies."